LiFePO4 Batteries for AWPs

-

Aerial Work Platform Battery Charger

Aerial Work Platform Battery Charger

-

24V 105Ah Aerial Work Platform Battery

24V 105Ah Aerial Work Platform Battery

S24105

-

24V 160Ah Aerial Work Platform Battery

24V 160Ah Aerial Work Platform Battery

S24160

-

48V 105Ah Aerial Work Platform Battery

48V 105Ah Aerial Work Platform Battery

S51105B

LiFePO4 Batteries for Forklifts

-

Forklift Battery Charger CHA20-110-200

Forklift Battery Charger CHA20-110-200

-

24V 230Ah LiFePO4 Forklift Battery

24V 230Ah LiFePO4 Forklift Battery

F24230Y

-

24V 100Ah Forklift Battery

24V 100Ah Forklift Battery

F24100M

-

24V 560Ah Lithium Forklift Battery

24V 560Ah Lithium Forklift Battery

F24560P

-

24V 150Ah LiFePO4 Forklift Battery

24V 150Ah LiFePO4 Forklift Battery

F24150L

-

24V 560Ah Lithium Forklift Battery

24V 560Ah Lithium Forklift Battery

F24560L

-

36V 690Ah Lithium Forklift Battery

36V 690Ah Lithium Forklift Battery

F36690BC

-

48V 420Ah Lithium Forklift Battery

48V 420Ah Lithium Forklift Battery

F48420CA

-

24V 160Ah Lithium-ion Forklift Battery

24V 160Ah Lithium-ion Forklift Battery

F24160

-

48V 560Ah LiFePO4 Forklift Battery

48V 560Ah LiFePO4 Forklift Battery

F48560BS

-

80V 690Ah Air-Cooled LiFePO4 Forklift Battery

80V 690Ah Air-Cooled LiFePO4 Forklift Battery

-

48V 690Ah Lithium Forklift Battery

48V 690Ah Lithium Forklift Battery

F48690BD

LiFePO4 Batteries for Golf Carts

-

Golf Cart Battery Charger

Golf Cart Battery Charger

-

36V 100Ah Lithium Golf Cart Battery

36V 100Ah Lithium Golf Cart Battery

S38100L

-

48V 65Ah Lithium Golf Cart Battery

48V 65Ah Lithium Golf Cart Battery

S5165L

-

72V 100Ah Lithium Golf Cart Battery

72V 100Ah Lithium Golf Cart Battery

S72100P-B

-

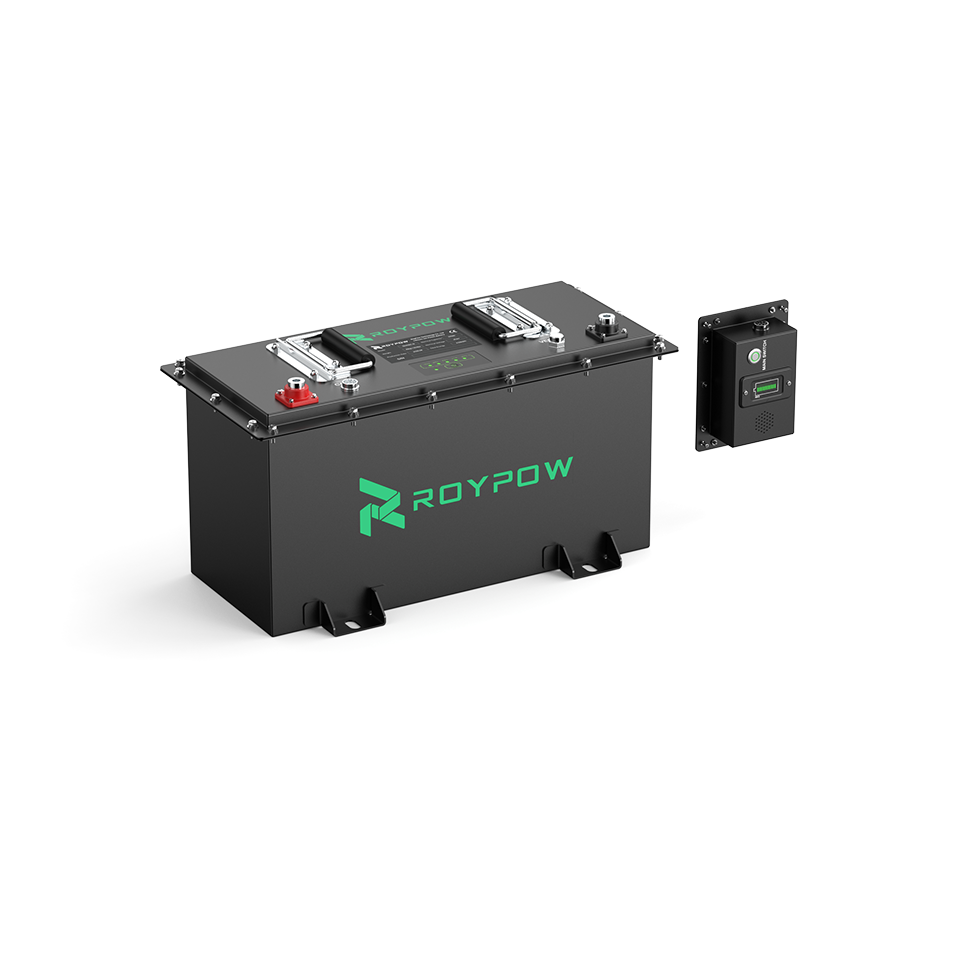

48V 150Ah Lithium Golf Cart Battery

48V 150Ah Lithium Golf Cart Battery

S51150P-A

-

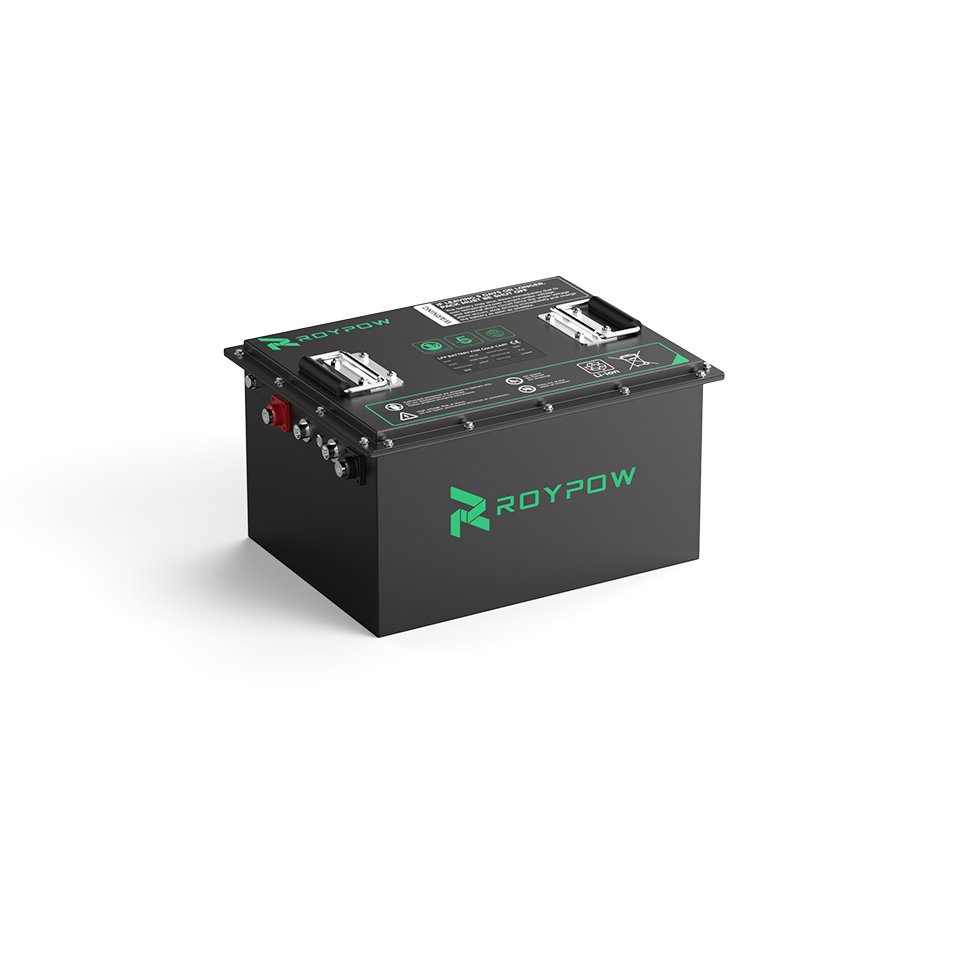

48V 100Ah Lithium Golf Cart Battery

48V 100Ah Lithium Golf Cart Battery

S51105

-

48V 150Ah Lithium Golf Cart Battery

48V 150Ah Lithium Golf Cart Battery

S51150L

-

48V 100Ah Lithium Golf Cart Battery

48V 100Ah Lithium Golf Cart Battery

S51100L

LiFePO4 Batteries for FCMs

-

1. What is an industrial battery?

+An industrial battery is a high-capacity rechargeable battery designed for industrial applications, including forklifts, electric vehicles, backup power systems, and large-scale energy storage. Unlike consumer batteries, industrial batteries are engineered for heavy-duty use, long cycles, and high safety standards.

-

2.What types of industrial batteries are available?

+Common types of industrial batteries include:

- Lead-acid batteries: Traditional and reliable for stationary and motive power applications.

- Lithium-ion batteries (LiFePO4, NMC): Have become the preferred option for their lightweight, fast-charging, long life, and maintenance-free capabilities.

- Nickel-based batteries: Less common, used in specific industrial equipment.

These batteries support various industrial applications such as industrial battery storage and electric-powered machinery.

-

3. How do I choose the right industrial battery?

+When selecting an industrial battery, consider:

- Voltage and capacity: Match the battery to your equipment’s requirements.

- Cycle life: Lithium-ion batteries often offer 3–5 times longer cycle life than traditional lead-acid.

- Application type: Forklifts, aerial work platforms, floor scrubbers, AGVs, AMRs, golf carts, and more may have different power requirements.

- Safety and certification: Ensure compliance with UL, IEC, or other relevant standards.

Consult industrial battery manufacturers or industrial battery suppliers for guidance on the best solution.

-

4. What is an industrial battery charger, and why is it important?

+An industrial battery charger is a device used to safely charge industrial batteries. Using the correct charger ensures:

- Longer battery life

- Efficient energy usage

- Safety during operation

Charger types may include standard chargers, fast chargers, or smart chargers with battery management systems (BMS) for real-time monitoring.

-

5. Where can I source industrial batteries and related solutions?

+You can obtain high-quality industrial battery supplies from reputable industrial battery manufacturers and industrial battery suppliers. When evaluating suppliers, consider:

- Working with certified suppliers ensures reliability and reduces operational risks.

- Range of industrial battery solutions offered, including chargers

- Product certifications (UL, CE, ISO)

- Warranty and after-sales support

-

6. What are the advantages of industrial battery power systems?

+Longer lifespan: Lasting 2–4 times as many cycles, which reduces replacement costs and downtime.

Faster charging: Reaching 80% in under two hours, and opportunity charging during breaks is safe and effective.

Virtually no daily maintenance: No watering, no equalization charging, and no acid cleaning like lead-acid batteries, saving both labor and operational costs

Consistent power output: Ensures that performance does not fade as the charge level drops, critical for demanding tasks like heavy forklift loads or aerial lifts at height.

Safer performance: Built-in battery management system (BMS) monitors temperature, voltage, and current in real time, protecting against overcharge, over-discharge, or overheating.

-

7. How can I maintain my industrial batteries?

+Proper maintenance helps extend their lifespan, reduce downtime, and ensure safe, efficient operation:

- Follow the manufacturer’s charging instructions using an approved industrial battery charger.

- Daily operation checks are required. Inspect connectors and cables for wear or looseness.

- Keep terminals clean and secure.

- Schedule periodic inspections for industrial battery power systems.

Monitor battery voltage, temperature, and state-of-charge remotely with Bluetooth or CAN monitoring for proactive maintenance.

If the industrial battery is in long-term storage, disconnect the battery, place it in a dry, ventilated area, and recharge every few months to maintain health.

Working with experienced industrial battery suppliers can guide maintenance and safety practices.